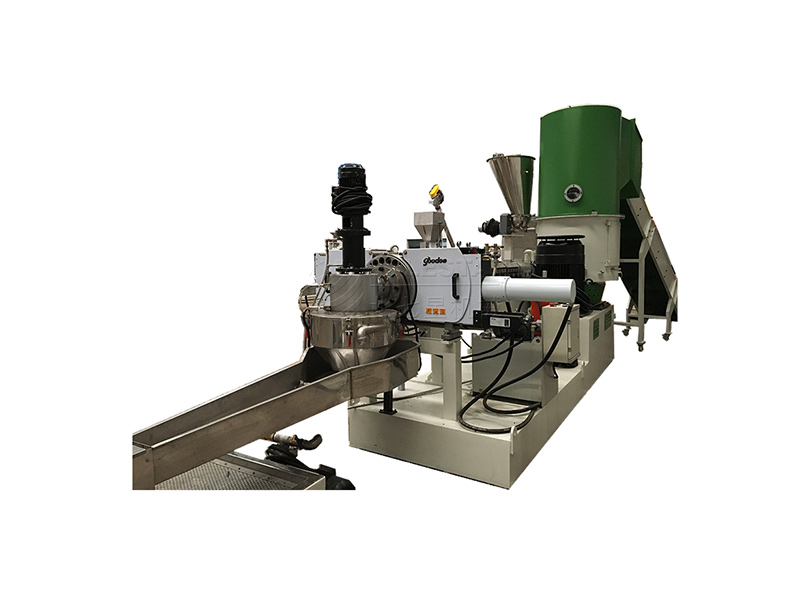

Siamani Tekonolosi Plastic PE PP Granulating Machine

Fa'amatalaga

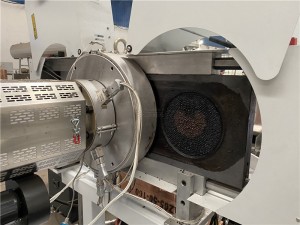

POLESTAR palasitika pelletizer masini / palasitika Granulators lea e maua ai le tufatufaina faamafanafana toniga ma homogenization e lelei mo le gaosia pellets palasitika i le toe faʻaaogaina faagasologa. O lo'o maua le masini pelletizer palasitika i le tasi (na'o le tasi le masini extrusion) ma le fa'atulagaina o tulaga fa'alua (tasi le masini extrusion autu ma le tasi masini extrusion lona lua laiti). E fautuaina le fa'aogaina o fa'asalaga fa'alua mo le toe fa'aaogaina ona o le fa'aleagaina o mea palasitika. O lo'o iai fo'i filifiliga 'ese'ese ole palasitika granule pelletizing tekonolosi e maua e pei ole su'e mata e fesoasoani i le vai ma le su'i mata lua-piston e fa'amautinoa ai e leai se fa'alavelave ile suiga ole lau. O le matou pusa fa'ameamea fa'alagolago e fa'avili lemu e fa'afefiloi ma fa'agaoioi le palasitika u'amea i totonu o le paelo. O le fa'ailoga e faia i le uamea fa'apitoa e fa'amautinoa mai le pala ma le abrasion. O le PID e pulea le vevela fa'atasi ai ma le ea po'o le vai e fa'amalieina ai le vevela galue. "Hot Cut" vai-mama mate mata pelletizing ma "Cold Cut" strand pelletizing auala e maua e faalagolago i lou manao.

Fa'atatauga

Mea mata: PE, PP Ata tifaga ma taga

Palasitika granulator masini / palasitika pelletizing masini / palasitika pelletizer masini ma agglomerator e mafai ona faʻaaogaina mo PE / PP ata tifaga po PP lalaga ato ma nisi parabolic pellet toe faʻaaogaina, o mea o le a faʻapipiʻiina atili faʻamalosi e agglomeration lea o le a faigofie ona lafo e extrude e extrude, lea e mafai ona ausia le maualuga maualuga 100-100kg / itula (faʻalagolago i manaoga o tagata faʻatau)

Tulaga Faatauva

1. Tulaga otometi maualuga, taumafai sili e faʻaitiitia lau tau i luga o galuega ma faʻamautinoa le maualuga o le gaosiga gafatia.

2. Faiga fa'aaumea (PLC tu'ufa'atasia & vavae'ese pule i masini ta'itasi) ma Touch screen panel, faigofie mo le fa'agaioiga, mata'ituina ma fa'alavelave fa'afuase'i.

3. O vaega uma e faʻafesoʻotaʻi ma mea palasitika ma vai e faia i le 304 sili ona lelei; Ia mautinoa e leai se filogia lona lua i fasipepa.

4. Siemens faʻafesoʻotaʻi, RKC pule vevela

Vaega Autu

1. Sili otometi, fa'aoga fa'aoga-fa'aoga, sili ona lelei, puipuiga o le siosiomaga ma le fa'asaoina o le malosi;

2. Pelletizing auala eseese, e pei o le mālūlū strand, vai-mama, ma lalo vai mo mea mata eseese ma manaoga gaosiga;

3. Tele-nofoaga screen changer ma mata otometi suiga mamanu e mafai ona faaitiitia galuega lima ma faaleleia le faagaoioiga faigofie;

4. Laasaga tasi ma le lua, tele-uso ma faʻamama faiga faʻamautinoa le maualuga ma oloa;

5. E fetaui lelei mo le gaosiga o mea eseese, e mafai foi ona mamanuina faapitoa le masini mo se mea e tasi poʻo mea eseese, lea e mafai ona faʻaitiitia ai le tau o tupe teufaafaigaluega.

Fa'amatalaga Fa'atekinisi

Laina e tasi agglomeration granulation laina

| Fa'ata'ita'iga | 70 | 100 | 120 | 150 | 180 |

| Tuuina atu (kg/h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Malosi'aga (kWh/kg) | 700-850 | ||||

| Malosiaga autu (kW) | 37 | 90 | 110 | 132 | 185 |

| Malosiaga fa'a'a'ele'ele(kW) | 30 | 55 | 75 | 110 | 132 |

| Siu le lautele pito i fafo (L/D) | 70(33:1) | 100(30-35:1) | 100(30-35:1) | 100(30-35:1) | 180(30-32:1) |

| Fa'amama fa'afu | Filifiliga | ||||

| Suia mata | Fa'atonuga masani | ||||

| Vai-mama granulation | Filifiliga | ||||

| Fa'ato'a fa'apalapala mālūlū | Filifiliga | ||||

| Fa'ameamea i lalo ole vai | Filifiliga | ||||

Laina fa'apipi'i fa'aopoopo fa'alua

| Fa'ata'ita'iga | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Tuuina atu (kg/h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Malosi'aga (kWh/kg) | 0.2-0.35 | ||||

| Malosiaga autu (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Malosiaga fa'a'a'ele'ele(kW) | 30 | 55 | 75 | 110 | 132 |

| Siu le lautele pito i fafo(L/D) | 70(25+12:1) | 100(25+12:1) | 120(25+12:1) | 150(25+12:1) | 180(25+12:1) |

| Fa'amama fa'afu | Filifiliga | ||||

| Suia mata | 2 seti o faatulagaga masani | ||||

| Vai-mama granulation | Filifiliga | ||||

| Fa'ato'a fa'apalapala mālūlū | Filifiliga | ||||

| Fa'ameamea i lalo ole vai | Filifiliga | ||||

Vaega o oloa

E te mana'o e fa'aopoopo le lagi i lau mamanu?

Fa'afeso'ota'i i matou i le asō mo se fa'atalanoaga fa'atusa.